BS EN 10208 Seamless Steel pipes for pipeline for flammable fluids. Technical delivery situations. Steel Pipes of requirement type B

OD:33.7-1626mm

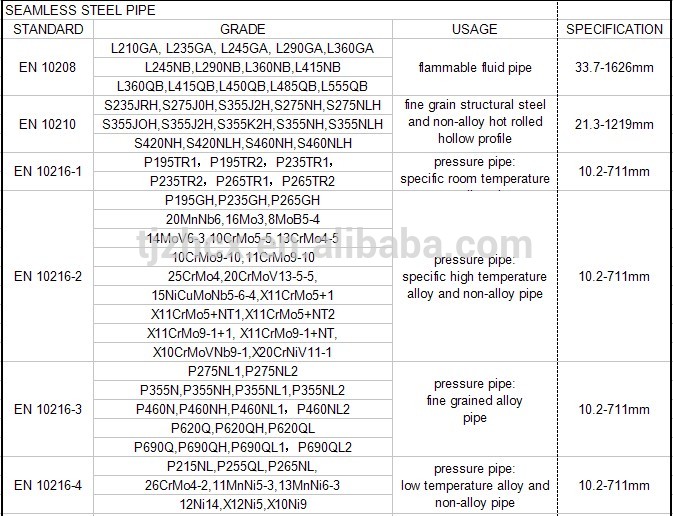

| Standard description |

The pipes are utilised for transporting gas, oil, combustible fluids with certain stress inside the mining, chemical, and power engineering sector.

The pipes are manufactured with all the diameters amongst 21,3 - 660 mm and using the wall thickness of as much as 40 mm within the case of hot rolled seamless pipes, and with all the diameters between 10,2 - 108 and together with the wall thickness of as much as ten mm inside the case of cold drawn seamless pipes.. |

| Manufacturing | seamless steel pipes and welded steel pipes. |

| Steel grades used | Requirement class A L210GA, L235GA, L245GA, L290GA, L360GA |

BS EN 10208-2 is the European regular that specifies the technical delivery conditions for seamless and welded steel pipes for the on land transport of combustible fluids mostly in gas provide systems but excluding pipeline applications inside the petroleum and all-natural gas industries. It consists of far more stringent quality and testing needs than those in BS EN 10208-1.

Steel pipes for pipeline transportation systems inside the petroleum and natural gas industries are covered by ISO 3183. BS EN 10208-2 specifies products with the identical (and additional) strength levels and partly related (but not identical) specifications as EN 10208-1 and EN 10208-2 and is with two extra annexes specifying deviating or extra needs also published as API Spec 5L.

BS EN 10208-2 does not apply to cast steel pipe.

It was the intention, when preparing this document, to avoid specifying the high-quality of line pipe to become utilised to get a certain application. Nonetheless, it was recognized that there are actually several high quality levels commonly made use of, and it was decided to reflect these inside the common by the differentiation involving two high-quality levels.

Firstly, the need was recognized to supply a standard top quality level. This really is designated requirement class A and considered in BS EN 10208-1.

Secondly, a lot of purchasers impose needs extra towards the basic regular, as an illustration concerning toughness and non-destructive inspection. This method is popular, as an example, for transmission pipelines.

Such enhanced needs are addressed in requirement class B and regarded in BS EN 10208-2.

For offshore applications and also other applications outside the scope of BS EN 10208-1 and BS EN 10208-2, other requirements may perhaps be applicable, e.g. ISO 3183.

The Charpy impact power needs within this document happen to be derived from established data, in accordance with EPRG recommendations, and are intended to prevent the occurrence of extended running shear fracture in pipelines transporting clean, dry natural gas. It truly is the duty from the designer to determine irrespective of whether these energy requirements suffice for the intended application. One example is, rich gas or two-phase fluids may well need additional testing to become carried out.

For pipes of requirement class B, a weld efficiency issue of 1,0 might be utilized in design calculations, because of the conditions specified for the manufacture of the pipes and for the testing with the tubes.

The selection of the requirement class will depend on lots of components: the properties in the fluid to be conveyed, the service conditions, design and style code and any statutory requirements must all be taken into consideration. BS EN 10208-2 provides no detailed suggestions. It is actually the ultimate duty of the user to choose the appropriate requirement class for the intended application.

This document combines a wide array of item varieties, dimensions and technical restrictions in accordance with the functional specifications for gas supply systems referred to in BS EN 1594 Gas provide systems. Pipelines for maximum operating pressure more than 16 bar. Functional needs.

Related post

Archives

-

Seamless steel pipe

- Line pipe

- OCTG pipe

- Mechanical steel pipe

- Structural steel pipe

- Boiler Tube

- ERW pipe

- SSAW pipe

- LSAW pipe

- Corrosion protection pipe

- Insulated pipe

- Abrasion resistant pipe

- Stainless steel pipe

- API pipe

- ASTM pipe

- Galvanized steel pipe

- Water pipe

- Gas pipe

- Carbon steel pipe

- Alloy steel pipe

- Hot rolled pipe

- black steel pipe

- Flange

Welded steel pipe

Special steel pipe

Pipes

Pipe Fittings

3 Comments

DIN 46Mn7 alloy seamless pipe,Usage: structure, casing and tubing for oil field, delivering liquid and gas, ordinary use and etc .

1. Type: Line Pipe 2. Standard: API 5L 3. Grade: A, B, X42, X46, X52, X60, X65, X70, X80 4. O. D.: 2.375"-10.750" 5. W. T.: 0.281"-0.365" .

seamless api 5l steel pipe in stock We have 4500ton seamless steel pipes API 5L X42 in our warehourse coating: External 3 layer PE 3mm,internally rounding oxygenic Product Name : Seamless steel pipes Specification : 219.1MM x 6.4MM x.

Gr.B 22" SCH XS Steel Pipe,1.OD:21mm-24mm,Thk:2mm-60mm 2.Length:5m-12m 3.Grade 10# 20# A53 A106 ST37 ST42 ASTM/SA A106 Gr.B 22" SCH XS 6M Seamless Carbon Steel Pipe .

JCOE Pipe,LSAW steel pipes /manufacture OD:325-1420MM WT:5-50MM API5L manufacture PSL1 and PSL2 Q235B/L245/Q345B/L290/L360.

standard steel pipe,seamless carbon standard pipe We offer seamless steel pipe /carbon steel pipes /alloy steel pipes/ galvanized steel pipes /ERW steel pipes /Square steel pipes.