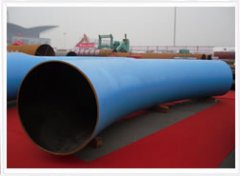

Longitudinally welded pipe

Longitudinal welded steel pipe

Custom Longitudinal steel pipe

Large Diameter Longitudinal Welded Pipe

Structure Custom Longitudinal steel Pipe

With more than 15 years' of welded steel pipe production experience and participation in government projects, we fullly comprehend the materials, production processing, testing control, therefore, our products fully comply with API, ASTM, GRA/GRB, BS1378-1985, DIN 2391 standard etc.

What we offering to you:

Longitudinal Girth Welded Steel Pipes:

The pipes with outside diameter from 508mm(20inch) to 3556mm(140inch), maximum length from 1500mm(59.055inch)up to 3000mm(118.110inch)

The pipes with wall thickness diameter from 7mm(0.276inch) up to 40mm(1.575inch)

Longitudinal Straight seam welded steel pipe:

The pipes with outside diameter from 508mm(20inch) to 2032mm(80inch), maximum length from 6000mm(236.220inch)

The pipes with wall thickness diameter from 7mm(0.276inch) up to 22mm(0.866inch)

Longitudial Welded Steel Pipe By Customized:

The pipes with outside diameter from 300mm(11.811inch) to 3500mm(137.795inch), maximum length from 800mm(31.496inch)up to 1500mm(59.055inch)

The pipes with wall thickness diameter from 20mm(0.787inch) up to 80mm(3.150inch)

Our Advantage:

*Reliable products

*Competitive price

*Flexible business cooperation

*ISO Certified processing

*100%tested products

*Earth-friendly products

*OEM Acceptable

*Small order available

*Professional service

*Cost saving shipment.

Welded steel pipe:

Welded steel pipe is steel plate with the bending deformation of round, square and other shapes and then welded into the surface of the pipe joints. Welded steel pipe used is steel or steel billets. We supply of welded steel pipe manufactiong process is simple, high production efficiency, many varieties of different specificatios, equipment, less captial, but the general strength less than seamless.

Since the 20th century, 30 years, with high-quality steel rolling prodiction, as well as the rapid development of welding and inspection technology advances, continually raising the quality weld, welding steel pipe increasing number of varieties and specifications, and in a growing number of areas instead of non-Steel Pipe, than the seamless steel pipe welded steel pipe and low cost, high production efficiency.

We will strictly test and check our products, such as steel surface quality should be smooth, not permit folding, cracks, delamination, take the existence of welding defects. Allowed no more than pipe wall thickness of the surface of a negative bias is zoned Road, scratches, weld dislocation, burns and other minor flaw. Allow welds and inner wall thickening seam welding bars there.

Welded steel pipe should be done mechanical performance test and flattening test as well ad the flared test, and to meet the standard requirements. Pipe should be able to withstand a certain degree of intemal pressure, when necessary, 2.5Mpa pressure test and maintain for one minute without leakage, permits the use of eddy current testing in lieu in of hydrostaitic testing. Eddy current testing according to GB7735 "steel tube eddy current test method "standard. Eddy current method is to probe the rack, the flaw with the weld to keep 3~5mm distance, by the rapid movement of the weld pipe to conduct a comprehensive scanning, eddy current flaw detection signal by the automatic processing and automatic sorting, achieve the detection purpose.

After testing with flying saw pipe length required to cut off, after turning off the assembly line aircraft. Pipe ends shall be flat head chamfering, print mark, finished tied packed hexagonal tubes factory.

Please consult us for any project or requirements.

| OD | Wall Thickness/mm | ||||||||||||||

| /mm | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.5 | 1.6 | 1.8 | 2 | 2.2 | 2.5 | 2.8 | 3 | 3.2 |

| Weight/(kg/m) | |||||||||||||||

| 5 | 0.055 | 0.065 | 0.083 | 0.099 | |||||||||||

| 8 | 0.092 | 0.109 | 0.142 | 0.173 | 0.201 | ||||||||||

| 10 | 0.117 | 0.139 | 0.181 | 0.222 | 0.26 | ||||||||||

| 12 | 0.142 | 0.169 | 0.221 | 0.271 | 0.32 | 0.366 | 0.388 | 0.41 | |||||||

| 13 | 0.183 | 0.241 | 0.296 | 0.343 | 0.4 | 0.425 | 0.45 | ||||||||

| 14 | 0.198 | 0.26 | 0.321 | 0.379 | 0.435 | 0.462 | 0.489 | ||||||||

| 15 | 0.123 | 0.28 | 0.345 | 0.408 | 0.47 | 0.499 | 0.529 | ||||||||

| 16 | 0.228 | 0.3 | 0.37 | 0.438 | 0.504 | 0.536 | 0.568 | ||||||||

| 17 | 0.243 | 0.32 | 0.395 | 0.468 | 0.359 | 0.573 | 0.608 | ||||||||

| 18 | 0.257 | 0.339 | 0.419 | 0.497 | 0.573 | 0.61 | 0.647 | ||||||||

| 19 | 0.272 | 0.359 | 0, 444 | 0.527 | 0.608 | 0.647 | 0.687 | ||||||||

| 20 | 0.287 | 0.379 | 0.469 | 0.556 | 0.642 | 0.684 | 0.726 | 0.808 | 0.888 | ||||||

| 21 | 0.399 | 0.493 | 0.586 | 0.677 | 0.721 | 0.765 | 0.852 | 0.937 | |||||||

| 22 | 0.418 | 0.518 | 0.616 | 0.7U | 0.758 | 0.805 | 0.897 | 0.986 | 1.074 | ||||||

| 25 | 0.477 | 0.592 | 0.704 | 0.815 | 0.869 | 0.923 | 1.03 | 1.134 | 1.237 | 1.387 | |||||

| 28 | 0.537 | 0.666 | 0.793 | 0.918 | 0.98 | 1.0412 | 1.163 | 1.282 | 1.4 | 1.572 | 1.74 | ||||

| 30 | 0.576 | 0.715 | 0.852 | 0.987 | 1.054 | 1.121 | 1.252 | 1.381 | 1.508 | 1.695 | 1.878 | 1.997 | |||

| 32 | 0.764 | 0.911 | 1.065 | 1.128 | 1.199 | 1.341 | 1.48 | 1.617 | 1.1819 | 2.016 | 2.145 | ||||

| 34 | 0.814 | 0.971 | 1.125 | 1.202 | 1.278 | 1.429 | 1.578 | 1.725 | 1.942 | 2.154 | 2.293 | ||||

| 37 | 0.888 | 1.059 | 1.229 | 1.313 | 1.397 | 1.562 | 1.726 | 1.888 | 2.127 | 2.361 | 2.515 | |

|||

Related post

-

May 6, 2015 -

May 6, 2015 structure tube

-

May 6, 2015 ERW STRAIGHT WELDED STEEL PIPE

Archives

-

Seamless steel pipe

- Line pipe

- OCTG pipe

- Mechanical steel pipe

- Structural steel pipe

- Boiler Tube

- ERW pipe

- SSAW pipe

- LSAW pipe

- Corrosion protection pipe

- Insulated pipe

- Abrasion resistant pipe

- Stainless steel pipe

- API pipe

- ASTM pipe

- Galvanized steel pipe

- Water pipe

- Gas pipe

- Carbon steel pipe

- Alloy steel pipe

- Hot rolled pipe

- black steel pipe

- Flange

Welded steel pipe

Special steel pipe

Pipes

Pipe Fittings

3 Comments

standard steel pipe,seamless carbon standard pipe We offer seamless steel pipe /carbon steel pipes /alloy steel pipes/ galvanized steel pipes /ERW steel pipes /Square steel pipes.

DIN 46Mn7 alloy seamless pipe,Usage: structure, casing and tubing for oil field, delivering liquid and gas, ordinary use and etc .

JCOE Pipe,LSAW steel pipes /manufacture OD:325-1420MM WT:5-50MM API5L manufacture PSL1 and PSL2 Q235B/L245/Q345B/L290/L360.

Gr.B 22" SCH XS Steel Pipe,1.OD:21mm-24mm,Thk:2mm-60mm 2.Length:5m-12m 3.Grade 10# 20# A53 A106 ST37 ST42 ASTM/SA A106 Gr.B 22" SCH XS 6M Seamless Carbon Steel Pipe .

1. Type: Line Pipe 2. Standard: API 5L 3. Grade: A, B, X42, X46, X52, X60, X65, X70, X80 4. O. D.: 2.375"-10.750" 5. W. T.: 0.281"-0.365" .

seamless api 5l steel pipe in stock We have 4500ton seamless steel pipes API 5L X42 in our warehourse coating: External 3 layer PE 3mm,internally rounding oxygenic Product Name : Seamless steel pipes Specification : 219.1MM x 6.4MM x.